ECM Unveils High-Torque, Ultra-Compact Servo Motor with Integrated Harmonic Drive Ahead of Automate 2025

ECM 's new servo motor delivers 18.8Nm of torque from just 0.57kg-achieving an exceptional torque-to-weight ratio in an ultra-compact footprint.

NEEDHAM, MASSACHUSETTS / ACCESS Newswire / May 6, 2025 /US electric motor design software firm ECM PCB Stator Tech , has announced the launch of its groundbreaking new servo motor featuring an integrated 50:1 gear ratio harmonic drive-engineered to deliver unmatched torque density, precision, and compactness. ECM 's new ‘Eight Ball ' motor solution will be on display at Automate 2025 (Booth 6223), alongside the company 's growing lineup of 0.5Nm and 2Nm Servo Evaluation Motors available for immediate purchase.

ECM 's ‘Eight Ball ' integrates a PrintStator-designed PCB Stator with a 50:1 harmonic drive, delivering an impressive 18.8 Nm of torque in a compact form factor.

Setting a New Standard for Compact High-Torque Motors

The Eight Ball addresses critical challenges faced by automation, robotics, aerospace, and medtech engineers: space constraints, weight sensitivity, and precision control. Despite its ultra-compact form factor (2.95" x 3.35" x 1.96") and minimal weight (0.57 kg/1.26 lbs), the Eight Ball generates an impressive 18.8Nm of torque-driven by an integrated harmonic drive and powered by ECM 's patented PCB Stator motor technology.

Equipped with dual encoders for closed-loop feedback, the Eight Ball delivers cog-free operation with pinpoint positional accuracy-making it ideal for robotic arms, precision automation, UAV systems, and medical devices where every gram and degree counts.

Innovation in Every Turn

By uniting high-torque harmonic drive technology with ECM 's award-winning PCB Stator design approach, the Eight Ball offers:

Exceptional torque-to-size performance

Energy efficiency gains through minimized inertia

Reduced raw material usage and system complexity

Flexible thru-hole design for seamless system integration

ECM 's new Eight Ball servo joins a broader suite of next-generation electric motor innovations-delivered through PrintStator SaaS , off-the-shelf PCB Stator Evaluation Motors , and full-service Motor Development offerings.

ECM also offers a wider range of PCB Stator Evaluation Motors, enabling businesses to quickly test and validate this innovative motor solution.

Servo Motors Built for the Next Generation

Alongside the Eight Ball, ECM is also showcasing its versatile 0.5Nm and 2Nm Servo Evaluation Motors at Automate 2025-enabling innovators to fast-track product development with highly efficient, lightweight, and precision-optimized servo solutions.

This launch is supported by a technical case study, which explores the engineering challenges that high-torque, space-constrained applications face-and how ECM 's integrated harmonic drive and PCB Stator architecture overcomes them.

Read the full case study here.

"The Eight Ball is a breakthrough in what 's possible for compact, high-precision motion control," said Brian Casey, CEO of ECM PCB Stator Tech. "By combining our advanced PCB Stator technology with an integrated harmonic drive, we 're empowering customers to meet-and exceed-the most demanding engineering challenges across robotics, aerospace, automation, and beyond."

About ECM PCB Stator Tech

The Leaders in PCB Stator Motor Innovation

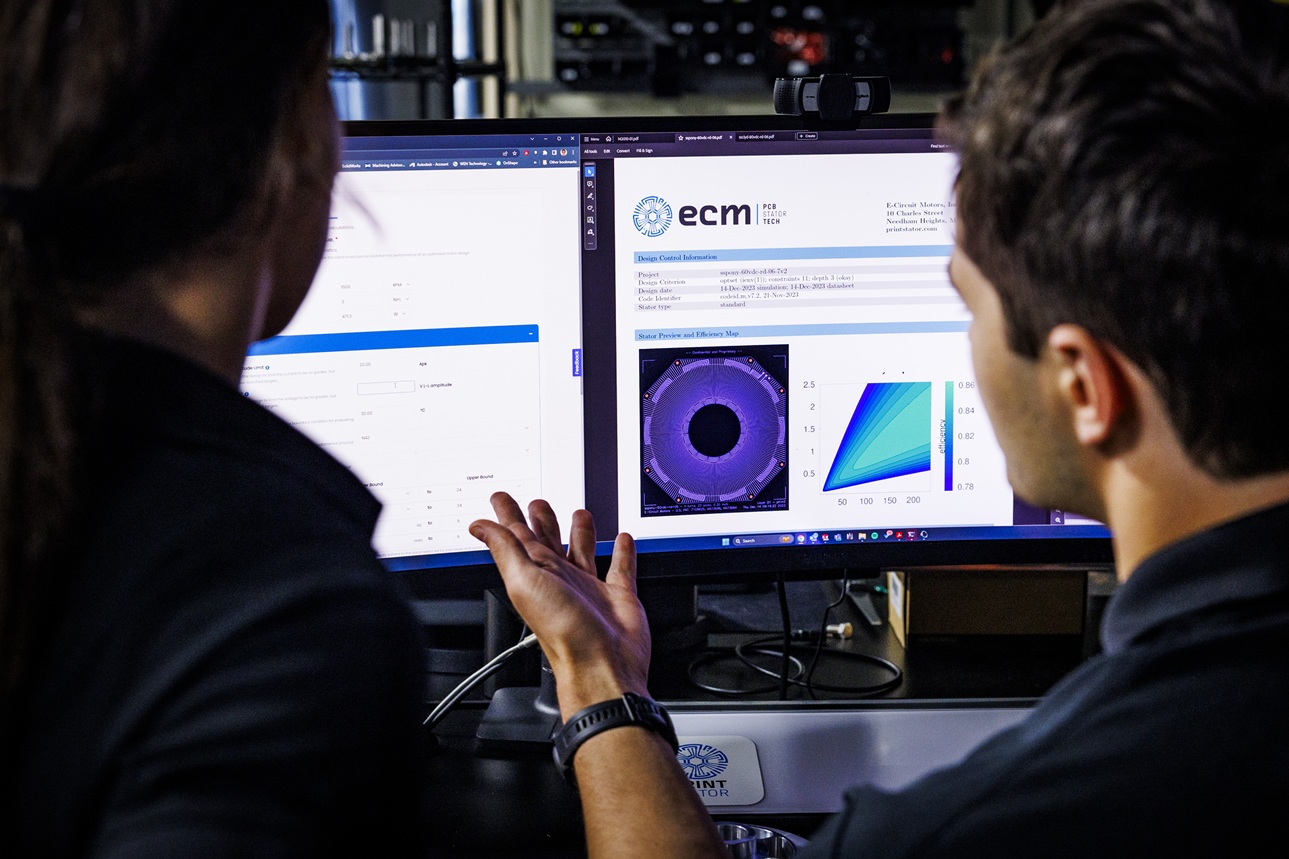

ECM PCB Stator Tech delivers the only full-stack solution for electric motor innovation-empowering partners to design, prototype, and optimize next-generation PCB Stator motors with unprecedented precision and speed.

Through our PrintStator Motor CAD platform and patented PCB Stator technology, ECM enables customers to overcome the limitations of traditional motors and rethink what 's possible. Our approach unlocks:

Compact, Lightweight Design : Ultra-thin motors that use up to 80% less raw materials

Unmatched Motion Performance : High efficiency, cog-free precision, reduced noise, and longer life cycles

Accelerated Speed-to-Market : Advanced software-driven optimization for rapid prototyping and deployment

ECM 's PrintStator Motor CAD software enables engineers and innovators to design PCB Stator motors in minutes.

From aerospace to automation, HVAC, consumer appliances and medtech, ECM partners with innovators to build electric motors that power the future.

ECM 's partners include consumer electronics leader Thrustmaster , publicly traded aerospace and technology company L3 Harris , global electronics manufacturer Celestica , marine and rail component leader B. Hepworth, global engineering and manufacturing services firm East West Manufacturing, and consumer electronics startup Nodo Film Systems .

ECM maintains offices in Boston (MA), Bozeman (MT), and business development representatives in Europe.

Learn more about ECM 's PCB Stator solutions and PrintStator Motor CAD platform at www.pcbstator.com and in these videos: "How Does a PCB Stator Work?" and "Designing Sustainable Electric Motors."

Contact Information

Sam Jones

Director of Marketing and Communications

sjones@pcbstator.com

SOURCE: ECM PCB Stator Tech

View the original press release on ACCESS Newswire

© 2025 ACCESS Newswire. All Rights Reserved.